Compression Springs

KLF is able to provide compression springs in a variety of shapes and sizes. A compression springs is a mechanical spring with elasticity, it is an open-coil helical spring, which usually coiled into a constant diameter shape, such as a cylindrical spring, conical spring, concave spring, or convex spring. We can provide carbon steel springs, stainless steel springs and non-ferrous alloy springs with wire diameter range from 0.1mm to 6mm. Our compression springs are primarily used in water dispenser, water cooler and air conditioners. Following shows the spring examples and custom made details.

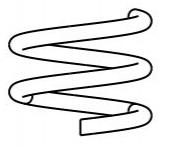

Compression Springs, Conical Springs, Tapered Springs

- KLF provides conical compression springs with the wire diameter range of 0.1mm to 1.5mm and made of a variety of materials. We use a CNC automatic spring machine, and a camless spring machine to manufacture the small tolerance precision spring.

The conical spring has a variable coil diameter. It has a large diameter at one end and a small diameter at the other end, with the diameter of the middle coil constantly changing.

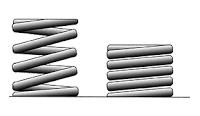

Compression Springs, Valve Spring

- Valve springs are a helical compression spring used to close or keep the valve closed. As a professional precision spring manufacturer, KLF is able to customize valve springs for a variety of valves and applications, such as valve springs used for automotive, natural gas, medical equipment, mining and other industries.

KLF produces valve springs in a variety of materials including high carbon steel wire, stainless steel wire, non-ferrous metal alloy wire.

| Compression spring types | Compression spring ends |

| KLF produces customized compression springs in a variety of shapes and sizes to meet industry standards and tolerance requirements. | Not only do we offer the end types listed below, but we also offer custom end services. |

Compression Springs with Conical Shape  |

open-ended open-ended |

Compression Springs for Valve  |

ground ended ground ended |

closed and ground ends closed and ground ends |

-

Carbon Steel Compression Spring for Electric Cooker

wire diameter: 0.5mm

Material: carbon steel wire

Features: great and stable elasticity

Applications: electric cooker -

Stainless Steel Compression Spring for Refrigerator and Fridge

wire diameter: 1.5mm

Material: stainless steel

Features: great and stable elasticity

Applications: refrigerator -

Stainless Steel Spring Guard for Gas Cooker

wire diameter: 0.3mm

Material: stainless steel

Features: great and stable elasticity

Applications: gas cooker -

Stainless Steel Compression Spring for Kettle

wire diameter: 1.0mm

Material: stainless steel

Features: great and stable elasticity

Applications: kettle

KLF utilizes advanced spring processing equipment, including a compression spring machine, bench drilling and tapping machine, grinding machine, milling machine and more, allowing us to manufacture the springs you need based on the parameters listed below, or a customer provided sample.

- Free length (F/L)

- Load length (L/L) and size

- Elastic parameter

- Maximum compression weight

- Maximum compression length

- Outer diameter (O/D), Inner diameter (I/D), Middle diameter (M/D)

- Wind direction: left-hand or right -hand

- End type

- Material and surface treatment

- Tolerances and working conditions

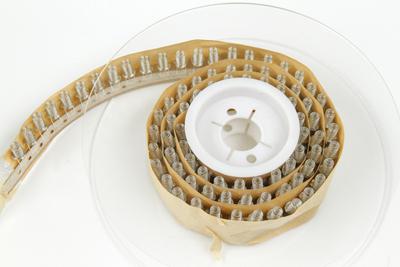

As a professional manufacturer of customized compression springs, KLF is able to design and precisely manufacture compression springs in a variety of shapes and sizes to meet strict customer requirements. In addition, we designed a braid packaging method to solve difficult installation problems and long term consumption for customers in mass production. The spring is braided with paper tape, allowing the customer to directly use the automatic insert machine in order to assemble the spring, at a speed of 300 springs/minute, thus effectively reducing customer production costs.