- Home

- Application

KLF is a professional precision springs and wire forms manufacturer. With nearly 20 years of production experience, KLF offers a variety of customized springs, including extension springs, compression springs, torsion wires, and wire springs. We have provided service to a wide array of industries, including hardware, home appliances, office supplies, sports equipment, kitchen and bathroom, and computer accessories.

Compression spring: Used for buffer, shock absorption and energy storage in mechanical equipment.

Compression spring requirements for home appliances: Elastic stability, fatigue resistance and corrosion resistance.

Compression spring applications: Rice cooker, electric kettle, toilet, and more

Extension spring: Used for bearing a tensile load

Extension spring requirements for home appliances: Fatigue resistance, corrosion resistance, tensile testing.

Extension spring applications: Fan, coffee machine, water heaters and more

Torsion spring: Used for compression, energy storage and the elastic component in transmission systems.

Torsion spring requirements for home appliances: Fatigue resistance, corrosion resistance and surface treatment.

Springs used in gym equipment require a greater strength, and thus, require a greater durability. To meet that need, KLF’s springs are manufactured using advanced processes to offer the required durability for gym equipment.

KLF is a professional spring manufacturer with the ability to offer a variety of parts services to gym equipment manufacturers. We customize springs in a variety of structures and features, including a spring hook end, weight resistance, length, surface treatment, materials to meet specific equipment movement requirements, and specific customer requirements.

Due to the high usage frequency of office supplies, springs used in these products must be high quality and have a long service life. Backed by professional spring production equipment and strict quality control, KLF uses a variety of testing instruments for different spring performance testing in order to produce reliable, durable springs according to customer requirements.

KLF is a customized precision spring manufacturer and provides compression springs, extension springs, and torsion springs for office supplies.

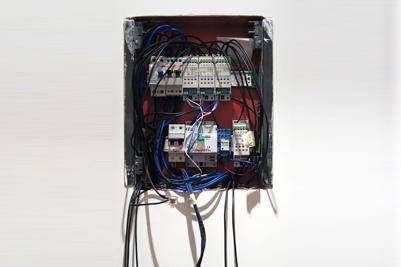

KLF provides precise manufacturing of springs, power rods, and metal stamping parts for a variety of electrical industrial applications, with a wire diameter of 0.01"-0.6". Some of these applications include assemblies, fixtures, powering and battery contacts.

KLF understands the key performance of each product, and takes that into consideration when customizing springs to meet customer requirements, thus ensuring we offer springs that meet all customer needs.

KLF accurately manufactures springs, wire springs and metal stamping parts used in a variety of computer applications, including compression springs for laptops, drives, mainframes and torsional springs for printer cartridges. In addition, our springs are customized according to customer needs with no stock, so please do not hesitate to contact us for all of your spring customization needs.

Computer and printer springs feature a high quality requirement since they are often operated in high temperatures, but do not require repeated maintenance in order to reduce costs. Because of this, KLF’s engineers offer both material advice and structural solutions before manufacturing the springs.

KLF has been dedicated to the production of precision springs for nearly 20 years, offering springs for use in water taps, nozzles, and toilet buttons. Thanks to our location in an industrial park known for spring manufacturing, and an advantageous geographical location, we have been able to reduce transportation costs, as well as overall costs- from raw material purchasing, all the way to shipment of the final materials.

KLF usually uses corrosion-resistant stainless steel material for kitchen and bathroom accessory spring manufacturing, as these springs are often exposed to moisture laden environments.

KLF provides precision manufacturing services for spring, wire forming and metal stamping parts used in construction and operations of various lawn, garden and outdoor power design applications. We use high-precision and highly efficient technology to produce durable and reliable components for lawn sprinkler heads, air inlet valves and more, so that customers are not only able to easily maintain their landscape, but maintain normal usage of outdoor power equipment.

Over the past 20 years, KLF has offered customization services for customers in the furniture and textile machinery industries, including springs, wire forming, and metal stamping parts.

From small hand tools used in furniture manufacturing, to large spool assemblies used in carpet manufacturing, our springs offer a reliable performance and a highly accurate performance.

KLF provides customization services for precise springs, such as mud pump springs, according to specific industry requirements for oilfield tools and mining applications. We use the following high quality spring alloy materials for spring production, because they are ideal for use in humid, corrosive environments in underground and coal mine wells: