- Home

- Manufacturing Capability

KLF specializes in the fabrication of mechanical spring products and our manufacturing capabilities are possible thanks to a number of investments and quality control measures. Our raw materials and surface treatments ensure that the springs are made from quality base materials for optimal performance and durability. Our production processes are developed to maximize efficiency and output. The equipment we use is made up of 40 sets of imported production machinery that can handle all of the rigors we put them through. To top it all off, we utilize specialized testing equipment in order to ensure our customers receive the best quality springs possible.

- Raw Materials & Surface Treatment

KLF can provide customers with standard and customized spring products. The raw materials we use in the production of our springs include stainless steel (17-7 and 316), high-carbon steel wire, alloy steel, high carbon steel wire, nickel-base alloy wire and hard-drawn steel wire.

- Production Process

The raw materials used in the production of KLF springs include carbon steel (62mn/72A/72B/82B/70#/T9A), stainless steel, nickel-coated stainless steel, copper and other materials. All purchased materials must be presented with material certification and undergo comprehensive quality testing.

- Manufacturing Equipment

KLF is engaged in the manufacturing of kinds of mechanical springs and owns over 40sets professional production equipment to automatically wind and form the springs.

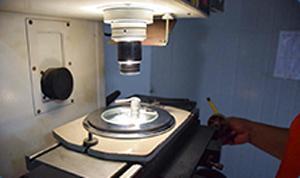

- Testing Equipment

Testing Equipment——DC low resistance test machine

Model: YD2511

Function: it can test resistance of push button springs.