- Home

- Manufacturing Capability

- Production Process

1. Purchasing required materials for production according to order requirements

The raw materials used in the production of KLF springs include carbon steel (62mn/72A/72B/82B/70#/T9A), stainless steel, nickel-coated stainless steel, copper and other materials. To ensure that the products shipped from our facilities are of the correct material and fabricated properly, we perform periodic inspections for quality and inventory. Before entering the factory for production, all purchased materials must be presented with material certification and undergo comprehensive quality testing.

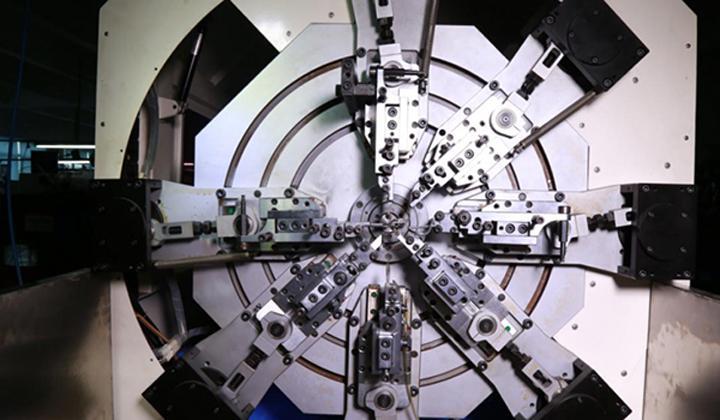

2. Machine in production

3.Heat treatment is performed depending on the material and customer requirements

By using our high-tech furnace, the microstructure inside the workpiece and the chemical composition on the surface of the workpiece can be altered to impart or improve the performance of the spring when it is put to use (including hardness, strength, toughness, ductility, processability, organization uniformity, elasticity, and fatigue life under variable load).

4. Sample testing equipment

5. Packaging according to customer requirements

6. Warehousing carried out in accordance with the type of spring and customer requirements